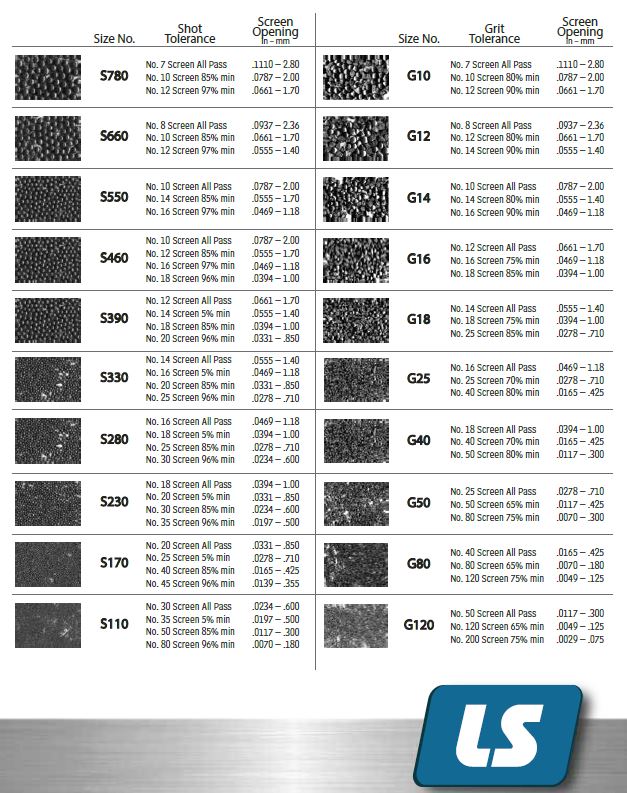

In the world of cleaning metal one of the most important is the selection of the right media. Effective use is important at various stages of primary metal production. Shot and grit and the right size selection and mix is crucial in achieving the finish you need, production times as well as minimizes excessive maintenance on equipment you are using to blast. Whether you decide on a manual application or fully automated system the right recipe matters.

Blast cleaning performs two basic functions; 1. Removal of surface contaminations, giving you a clean surface, which aids in inspection and finish process. 2. Surface prep providing a surface profile for painting, bonding’s and coatings.

Steel abrasive has 2.5 X’s more impact-force than sand, size for size at the same velocity. So, when using a larger size than sand its impact force would be many times greater creating a faster and better clean. Which is why moving from a manual blast to an automated one can increase your speed by 10X or more. Making a huge impact in your production as well as providing a more uniformed finish.

An effective work mix contains a properly balanced distribution of large, medium, and smaller particles, which is filtered and maintained in an reclaim and air wash system. Out of balanced work mixes results in extended blast times or re-blasting, which can have costly effects to productivity and operation costs.

Steel shot cleaning is not a one size fits all. The materials you’re working with thickness and density will contribute to your media selection and well as your overall goals in finish. If you’re working with a mixture of materials, there are things like VFD’s (controlling the RPM’s of the throw) or Magna Valves (controlling the amount of media in the throw) that can be added to an automated process as well as HMI/PLC for recipe control. Giving you more control in the results.

With all the contributing factors in media, selection can be overwhelming and costly in your bottom line if the wrong media is used. Talk to an expert, test your selection, be alert to preventive maintenance of your equipment and make the most of your blasting process.

LS Industries has worked with thousands of companies in the last 46 years in finding the right balance. We would love to help you find the right recipe!

Melissa Gibson

East Coasts Sales