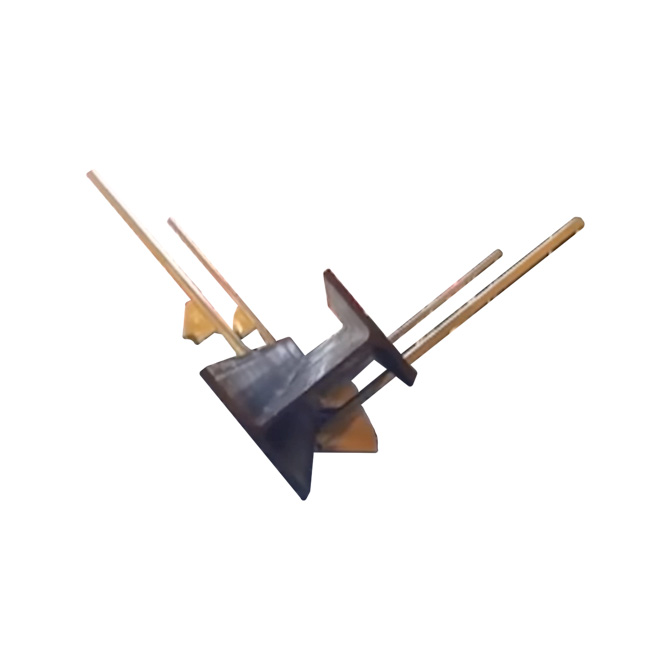

Flippers

LS Industries Flippers – Automated Part Flipping for Safer, Smarter Material Handling

LS Industries Flippers are designed to enhance automation and safety by automatically rotating or repositioning parts during your production or finishing processes. Built for heavy-duty industrial applications, these systems eliminate the need for manual flipping—reducing operator fatigue, increasing throughput, and ensuring consistent part orientation for downstream operations such as blasting, washing, coating, or assembly.

Our flippers integrate seamlessly into automated lines or can function as standalone units. With rugged steel construction and programmable control options, LS Flippers are built to handle a wide range of part sizes, weights, and geometries—improving both safety and efficiency in your operation.

Key Features:

- Heavy-duty steel frame designed for industrial use

- Automated part flipping eliminates manual handling and increases safety

- Compatible with robotic, conveyor, or in-line systems

- Customizable configurations to suit part size and orientation needs

- Variable speed and programmable motion controls for precision handling

- Helps maintain consistent orientation for blasting, painting, coating, or welding

- Ideal for cylinders, castings, weldments, and large fabricated parts

- Reduces labor costs and worker strain, while improving process flow

Whether you're working with heavy structural components or delicate parts requiring precise orientation, LS Industries Flippers provide a reliable, automated solution for safe and streamlined material handling.

Why Choose LS Industries?